Boehringer Ingelheim

Research-based pharmaceutical companies impose very high security standards on themselves for good reason, as they are potential victims of cyberattacks and espionage attempts.

Einsatzgebiet

Digital room signage

It is no different at Boehringer Ingelheim. Its systems must be particularly secure and therefore meet high standards. The company checks this regularly. One measure is to separate the systems from the office network. Each monitor is assigned a separate port, which is checked via IT security. The biopharmaceutical company has thus survived the attacks to date unscathed.

Monitors as an important work aid

These monitors have been supplied by the Mönchengladbach-based IT service provider Rein Medical since 2019. The company and its solutions also underwent a security check before installation. Boehringer Ingelheim relies on eight OPERION monitors with a screen diagonal of 24 inches and two monitors with a screen diagonal of 55 inches in its laboratories and work areas. The monitors are only used to display information. The 24″ displays also give employees access to the Manufacturing Management Software (MMS), the integrated software for automatic production planning and control.

They can use it to enter data centrally, operate workstations and control systems. In the selection process, the people responsible at Boehringer Ingelheim looked at a whole range of monitors from different manufacturers and assessed them according to previously defined criteria. In the end, the decision was made in favor of Rein Medical’s solutions because the company found a broad portfolio and many different sizes. The monitors have also fulfilled other essential requirements: They can be treated with commercially available cleaning agents, have a retractable keyboard and meet all fire safety and other specifications of the pharmaceutical company. The introduction of the monitors went as smoothly as the system selection. The displays run with high performance. As the terminals are connected to the room information system via a terminal server, there is only one point that needs to be maintained. The electronic door signs also perform reliably.

Knowing outside what happens inside

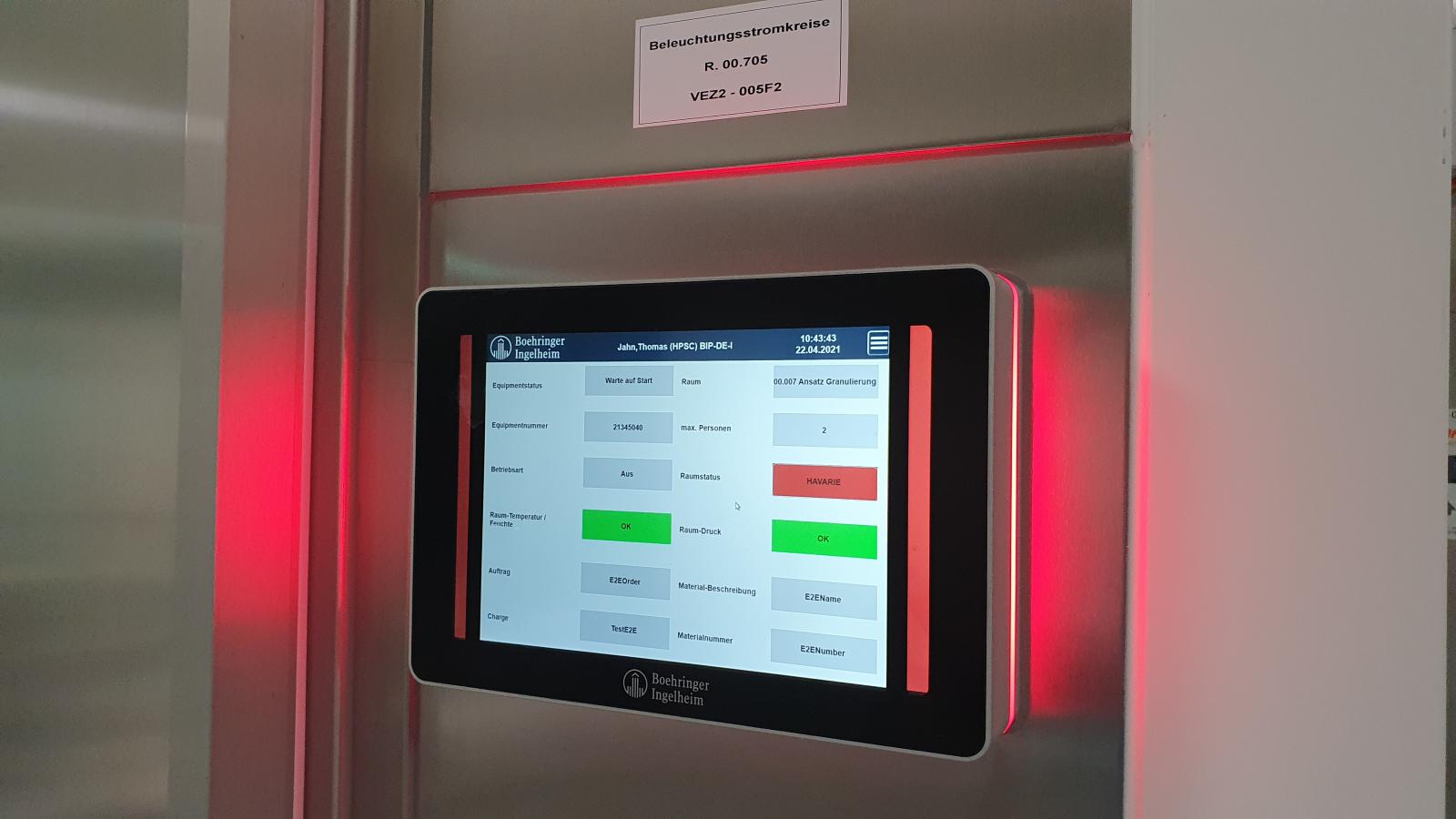

This refers to the 40 DOORSIGNs that Boehringer Ingelheim has been using since April 2021. “The customer’s employees saw the digital door signs during a meeting at our headquarters in Mönchengladbach and were immediately interested,” recalls Dirk Lambertz, the sales employee responsible for the project at Rein Medical. “They were particularly impressed by the LED status display, which is unique in this form.” The option of adding individual content to the door sign was also convincing. At the time, Boehringer Ingelheim needed a digital display to provide employees with important room and equipment information on site. Once again, the display had to meet the high requirements for peripheral devices within the production rooms. Once the cleanroom suitability had been successfully tested, the DOORSIGN displays could be integrated into the IT infrastructure without any problems. The great flexibility of the electronic door signs was helpful here. The Automation Engineer sees particular highlights of DOORSIGN in the integrated LED frame, as well as the possibility of control both via the hardware contacts and via the software. “These control options are central to GxP alarms for critical products,” explains Automation Engineer Thomas Jahn. The data displayed comes directly from the company’s internal building and room information system and is shown on the DOORSIGN displays. This gives employees a better overview of what is happening in the laboratories and production rooms. DOORSIGN was easily integrated into Boehringer Ingelheim’s existing IT infrastructure and offers great added value thanks to its transparent processes.

High satisfaction

Thomas Jahn sees the collaboration with Rein Medical as positive: “The introduction of all components went smoothly. When problems did occur, we always received help quickly. We were also always able to make an appointment quickly with the support team.”